Virtual HSE Assistant

Customized for Oil and Gas

Your Exceptional AI tool for Empowering HSE, Turning Data into Assets and Accelerating Risk assessment.

A Boundless HSE Team – Build it!

Virtual HSE Assistant

Customized For Oil And Gas

Your Exceptional AI tool for Empowering HSE Team

A Boundless HSE Team – Build it!

News & Articles

How AI Can Make Toolbox Talks More Impactful?

How AI Is Driving a Safer Future for Heavy Industries — Our Story with KAEFER

Artificial Intelligence is making headlines — but at VEUNEX, we’re more focused on making impact. In collaboration with KAEFER, we...

Announcing Our New Head Office in Aberdeen!

We are thrilled to share some exciting news: we have officially opened our new Office in Aberdeen! This strategic move...

How does AI empower HSE teams to overcome Monkey Board challenges?

Life Lost, Lessons Learned: Refinery Tragedy and AI’s Promise

How can AI improve fire safety in the workplace?

Why Choose Us as Your Trustworthy Partner?

Harnessing the power of cutting-edge AI and digital innovation, our mission is not just to solve your problems, but to forge enduring partnerships that stand the test of time.

+27%

Improved

Profitability

+36%

Improved

Efficiency

-28%

Decreased

Downtime

+32%

Improved

Quality

Solutions For Heavy Industries

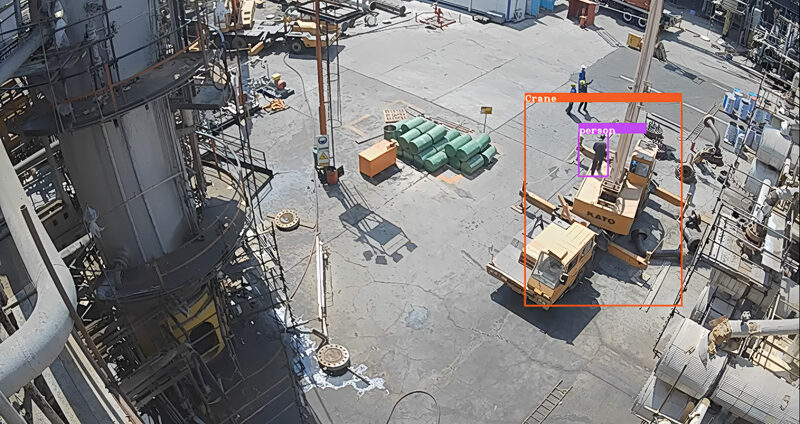

The Veunex technology solution not only manages risks but transforms HSE in drilling rigs, refineries, fabrication, and mining. Discover how we’re revolutionizing heavy industries.

Drilling rigs

magnify HSE impact

It is Impressive, This type of AI Analytics can show us two different worker behaviors. One is scared of the height and the other one is a kind of reckless to stand on the edge and rely on his equipment waiting for the next job.

Richard Lively- Rigs superintendent- Petronas

Refinery

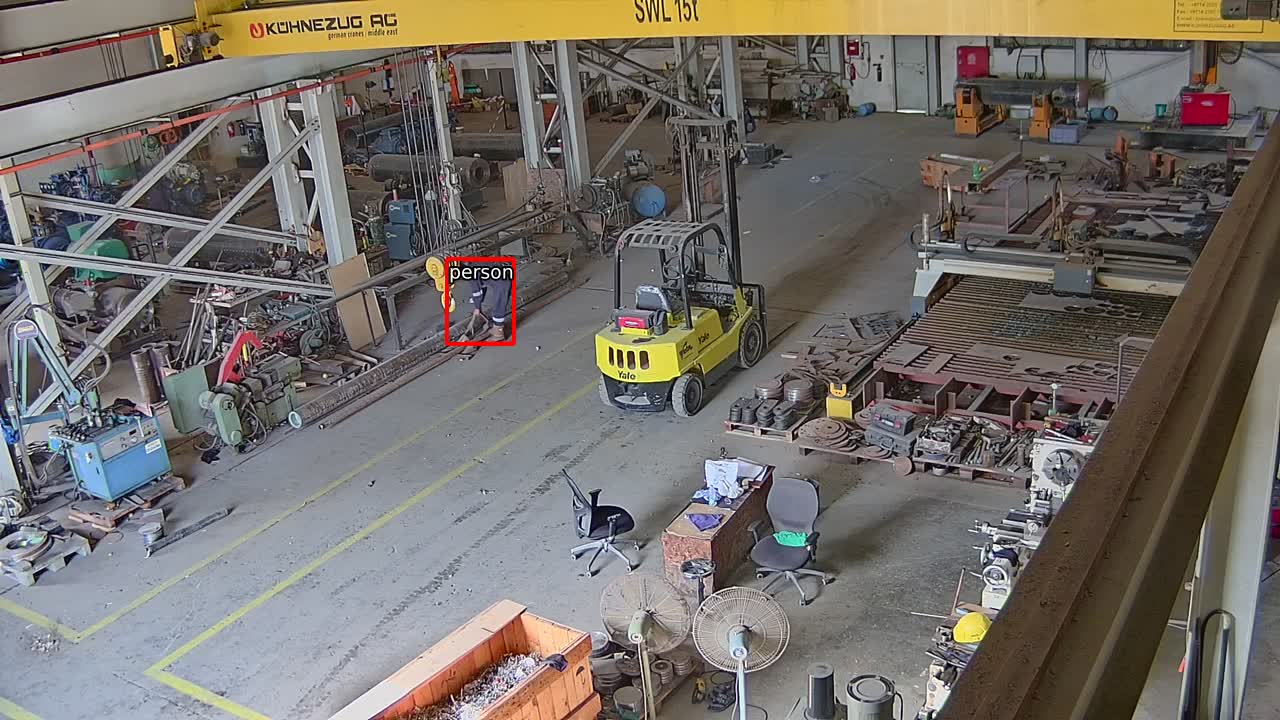

Fabrication

Build A Boundless Team

It is Working Perfectly and we can Monitor a Big Fabrication site with the power of AI coverage saving time and energy.

Vinek Deshwal-Principal HSES Advisor- McDermott

Unleash the untapped power of your data

unlock a world of boundless possibilities

Proactively Mitigate Risks

Turbocharge your profitability!

Take your data to the next level!

Resources

- Blog

- Case Study – Drilling Rig

- Case Study – Fabrication Site