AI holds the promise of revolutionizing HSE on the monkey board, and for compelling reasons. The proven machine learning capabilities of AI offer significant potential for maximizing workplace safety, even in the most perilous environments.

The monkey board, also known as the “diving/pipe racking board,” serves as a crucial platform located on top of the oil rig derrick tower, where essential tripping out/in or casing operations are conducted by derrickman. Its height can reach up to 90 feet or 27 meters, depending on the derrick structure and rig requirements.

Given the inherently hazardous conditions on the pipe racking board, including working at heights and working alone, accident rates remain alarmingly high. Human errors stemming from ignorance, overconfidence, and fatigue further exacerbate the likelihood of accidents.

Prioritizing the establishment of optimal safety practices is paramount here. However, traditional systems have fallen short in delivering effective results, prompting the integration of AI to drive significant improvements.

In this article, we will explore four ways Veunex customized AI can enhance HSE on the monkey board, empowering managers and HSE professionals with insights into the manifold benefits AI brings to workplace safety.

Table of content

Accelerating Risk Assessment

Conducting risk assessment stands as a cornerstone of HSE responsibilities, forming a vital part of their primary tasks. Before each operation, HSE professionals must meticulously review risk assessments, integrating any new findings to ensure accuracy. However, this process is often time-consuming and demands precise data.

Fortunately, the integration of AI and computer vision technologies offers a solution. By harnessing these tools, HSE personnel gain access to meticulously prepared, reliable data sets that seamlessly integrate into the risk assessment process. This integration not only expedites the assessment process but also enhances its accuracy.

With AI models trained the vast amount of gathered operational data from various rigs, risk assessment procedures can be significantly accelerated. These AI models empower HSE professionals to comprehensively evaluate all potential risks, aligning with operational specifics and regulatory guidelines such as API 54. As a result, every conceivable risk is thoroughly considered, leaving no room for oversight and providing assurance that safety measures are robustly implemented.

Enhancing Compliance Control

Enhancing compliance control on the monkey board of a drilling rig, particularly in the context of the Derrickman’s critical and hazardous responsibilities, demands attention to safety protocols and regulations. Despite the presence of dedicated Health, Safety, and Environment (HSE) personnel on-site for monitoring various rig operations, the sheer complexity and intensity of the tasks involved can occasionally lead to oversights, potentially jeopardizing the safety, notably regarding crucial measures like body harness tie-offs.

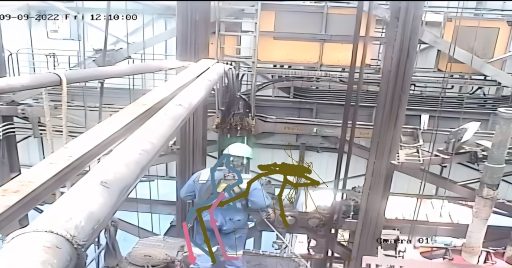

Integrating AI technology with surveillance cameras offers a transformative solution to bolster compliance monitoring effectively.

By leveraging AI algorithms to detect deviations from established safety protocols in real-time, any lapse, such as a failure to properly secure a body harness, can be swiftly identified and flagged to the relevant HSE personnel. This proactive approach not only mitigates the risk of accidents but also ensures prompt intervention when necessary, safeguarding the well-being of the Derrickman and all personnel involved with the rig operations.

In essence, the integration of AI-driven surveillance systems represents a pivotal advancement in enhancing compliance control, offering a robust mechanism for preventing potential safety breaches and upholding regulatory standards with heightened surveillance. This includes:

- Detecting PPE violations

- Preventing poor housekeeping

- Preventing dropped objects

- Monitoring lighting levels

These measures collectively ensure a safer working environment on the drilling rig, reducing the risk of accidents and prioritizing the well-being of all personnel involved in rig operations.

Automating Reports and Monitoring

HSE professionals often invest significant time completing checklists, writing reports, and doing site visits. AI integration offers a transformative solution, automating many routine tasks and empowering them to concentrate on critical matters, thus markedly enhancing and improving drilling rig HSE.

Essential reports can be generated instantly, furnishing comprehensive documentation for pre-operation meetings.

Furthermore, a wealth of engaging materials can be shared with new staff, facilitating their comprehension of challenges in highly effective ways—all effortlessly generated by AI.

With 24/7 monitoring, HSE personnel need not fret about physical presence across all rig locations; real-time access ensures nothing escapes attention. Moreover, manual checklist completion becomes obsolete with AI handling the task, consolidating all data seamlessly

AI-Generated Insights (behavioral safety)

Artificial intelligence doesn’t just streamline workflows for HSE teams through automation; it also unveils new insights into human behavior. Take, for example, our collaboration with Petronas, where Veunex identified distinct behavioral patterns in two different derrickmen. This revelation surprised the Petronas Rigs superintendent, demonstrating the power of insightful narratives generated by AI.

The depth of understanding provided by AI-generated narratives enables HSE teams to fine-tune their strategies with precision, fostering a culture of safety and well-being. By adapting plans based on these insights, organizations can proactively mitigate risks, enhance operational efficiency, and ultimately safeguard the health and safety of their workforce.

In conclusion, AI empowers the HSE team to excel in every aspect.

As outlined above, the integration of artificial intelligence holds immense potential for bolstering the expertise of oil and gas HSE teams, leading to a substantial enhancement in health and safety practices on drilling rigs. By leveraging AI-integrated cameras, HSE personnel can confidently ensure the safety of derrickmen on the monkey board. Furthermore, these technologies extend their impact beyond mere surveillance; they facilitate streamlined communication across sectors, consolidate data into a single accessible place, and enforce restricted access to critical areas such as the derrick. Such measures contribute significantly to fortifying the overall safety of the derrick structure, guaranteeing that all safety protocols are rigorously adhered to. For further exploration of the myriad possibilities AI offers in safeguarding the well-being of derrickmen, click here and let’s continue this discussion!

Veunex Virtual HSE Assistant

in Practice

Empower HSE team to

slash monkeyboard risks!

In collaboration with Petronas, OQ, and Aramco, Veunex has transformed safety on numerous offshore and onshore rigs. Discover our success stories to see how we’ve effectively tackled MonkeyBoard safety issues and empowered HSE teams to enhance their safety practices.

We will get back to you as soon as you unlock the resources.